15/01/26

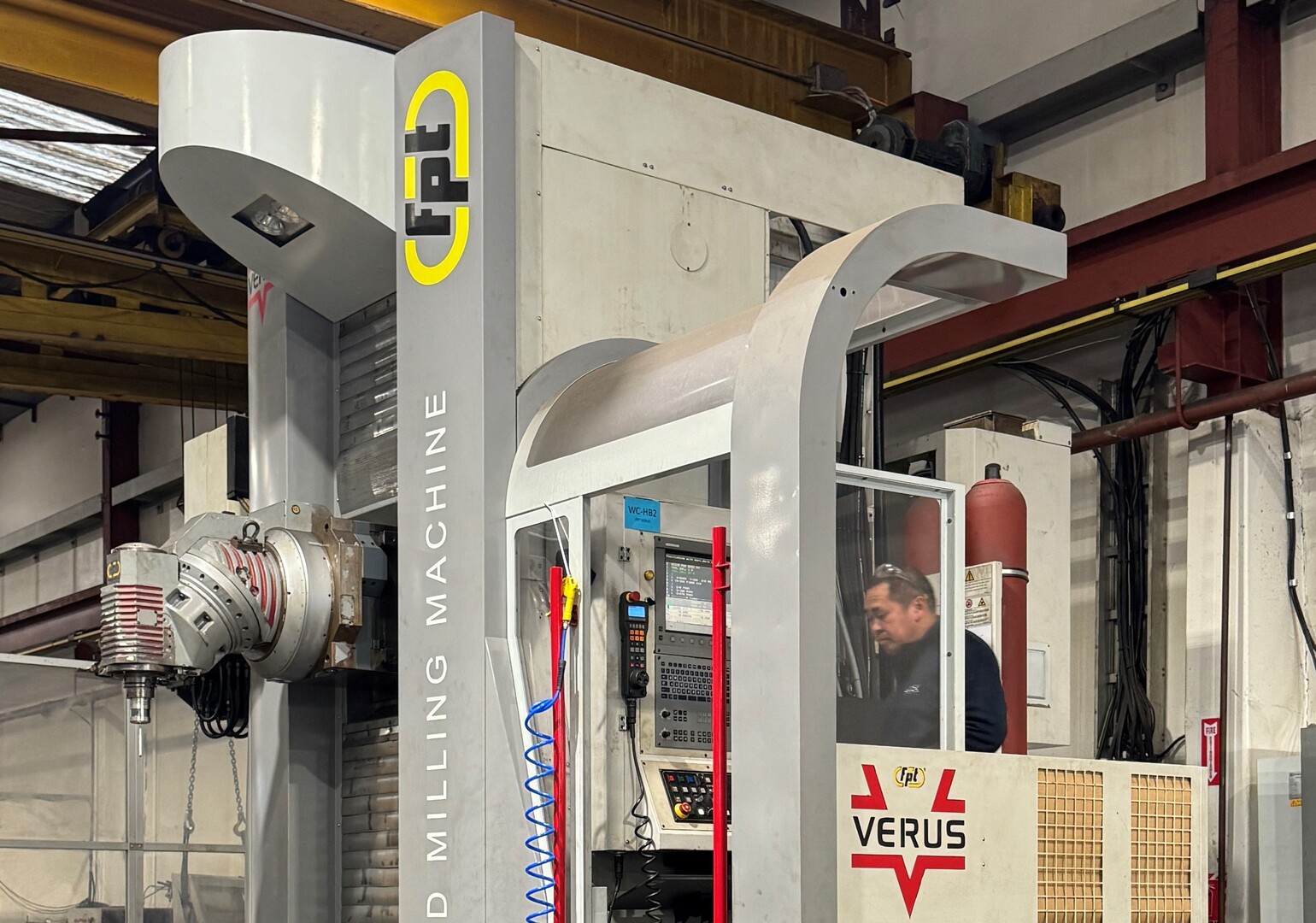

Track Industries has been featured in NZ Engineering News, recognising our continued growth and leadership in the New Zealand machining industry. The feature highlights how our investment in world-class machining technology — including the Italian-built FPT Verus milling machine — has strengthened our ability to deliver large, complex, and high-accuracy machining projects for demanding industries across New Zealand.

Track Industries has been featured in NZ Engineering News, recognising our continued growth and leadership in the New Zealand machining industry. The feature highlights how our investment in world-class machining technology — including the Italian-built FPT Verus milling machine — has strengthened our ability to deliver large, complex, and high-accuracy machining projects for demanding industries across New Zealand.

Business development and engineering manager, Danny Crawford, says the multi-axis travelling-column machine is already proving its worth. “This platform gives us the reach, rigidity and control to tackle complex parts in fewer set-ups,” he says. “For large-format work, the Verus layout is a proven way to keep tolerances tight over distance.”

Manufactured by FPT Industrie in Italy, the Verus has been engineered for precision, flexibility, and repeatability across demanding sectors, including energy, rail, and general engineering. Its multi-axis configuration allows for intricate machining of large workpieces in a single process, reducing time and potential error. “We’re set up for odd shapes and difficult access,” Crawford says. “With the right jigs, fixtures and CAM integration, we can approach tricky jobs efficiently and keep costs predictable.” He explains that Track’s customers are increasingly looking for partners who can handle every stage of a project – from design through to finished component – without the delays of multiple subcontractors.

“At Track, we’re recognised for our extensive portfolio of machine tools, especially in large format, with the new FPT milling machine adding nicely to this capability and capacity. Our customers respect us for the vast experience of our tradesmen and management team, who are experts in finding innovative and effective solutions to bring complex items into tolerance and within budget.” The Verus also complements Track’s long-standing expertise in repair and salvage machining. “We identify the correct repair route – welding, metal spray, plating or automated bore welding – then pre-machine, restore and finish to size. If required, we reassemble and function-test. This approach extends the life of valuable assets and keeps the critical plant up and running.

Alongside contract machining, Track continues to provide production machining using CAD/CAM and multiple-pallet technology to deliver economic, high-volume output. “When volumes climb, we can move into repeatable, economical production without re-engineering the process. Several of our machines feature CAD/CAM and pallet systems; combined with our jig and fixture experience, they make us well equipped for consistent results.” Design-to-manufacture capability is another core strength. “We use Autodesk products to produce 3D models, 2D drawings and CAM interface." Crawford says that working “hand-in-hand with our customers allows us to develop concepts that can be manufactured efficiently and meet or exceed their requirements.” He notes that Track’s integrated approach means clients can rely on a single supplier from the initial fabrication to on-site installation. “We can coordinate metal fabrication in-house or through our partners, then machine, fit and install. From emergency breakdowns to planned shutdowns, we have the resources to make it happen.”

Quality assurance remains central to the company’s offering, and the company can facilitate third-party destructive and non-destructive testing through local agencies and provide feedback on metallurgy, such as material type and hardness. Crawford believes the Verus investment strengthens Track’s role as a one-stop engineering partner for New Zealand industry: “Our focus is always on practical outcomes – shorter lead times, fewer set-ups and parts that meet tolerance without drama. If it’s big, awkward or accuracy-critical, that’s where the Verus helps us add certainty,” adds Crawford.

*published in NZ Engineering News, December 2025, pages 9-10.